What is a Prefab Building and How Does It Work?

Prefab buildings have gained significant traction in the construction industry. A report by Grand View Research states that the global prefabricated buildings market is expected to reach $302.5 billion by 2025. This surge is driven by the need for sustainable, efficient, and rapid construction methods. Prefab buildings offer streamlined processes that minimize labor costs and construction time.

However, the perception of prefab buildings is mixed. While some see them as cost-effective solutions, others may view them as less durable. This dichotomy prompts critical examination. Are these structures truly reliable? Moreover, the design options can appear limited. It's essential to weigh these aspects against the undeniable benefits prefab buildings offer.

As we explore what prefab buildings are and how they work, we'll look closely at the practical and conceptual challenges involved. Understanding the innovations and setbacks within this realm will help clarify their role in the future of construction. The journey into prefab buildings reveals both promise and potential pitfalls, inviting deeper consideration of their place in our built environment.

What Are Prefab Buildings? A Comprehensive Overview

Prefab buildings, or prefabricated structures, refer to buildings made from factory-produced components. These components are assembled on site, allowing for quicker construction times. They can be homes, offices, or even schools. The method reduces waste and can minimize costs, but it also has its drawbacks.

One appealing aspect of prefab buildings is their flexibility in design. Customizable modules can be combined in various ways. However, this adaptability may sometimes lead to design challenges. Achieving a balance between aesthetic appeal and functionality can be tricky. If the design is too complex, it may increase costs and time during assembly.

Prefab buildings can also face issues with durability and quality control. Although they are generally built to standards, variations can occur. Weather impacts and manufacturing flaws can affect the final product. It's essential to carefully evaluate manufacturers to ensure quality. Not all prefab options are the same, and some may not meet local codes effectively.

The Manufacturing Process of Prefab Structures: Key Steps Explained

Prefab buildings, short for prefabricated structures, are created off-site before being assembled at their final location. The manufacturing process for these buildings includes several key steps that enhance efficiency. In the first phase, materials are selected based on project requirements. These can range from wood to steel. Accuracy is crucial at this stage, as it lays the foundation for everything that follows.

Next, components are manufactured in a controlled environment. This often leads to faster construction times. Walls, roofs, and floors are built with precision. However, achieving consistency can sometimes present challenges. Variations in materials or human error can affect quality. After manufacturing, the parts are transported to the construction site. Care must be taken during transportation. Damage can occur if pieces are not secured properly.

Finally, onsite assembly begins. The sections are put together based on detailed blueprints. While the process is efficient, weather conditions can still pose problems. Rain or high winds may delay work. Additionally, not all teams are equally experienced with prefab structures, leading to potential setbacks. Although prefab buildings promise many benefits, attention to detail throughout every step is vital for success.

Prefab Building Manufacturing Process

This chart illustrates the key steps in the manufacturing process of prefab structures, showcasing the time allocation for each stage involved.

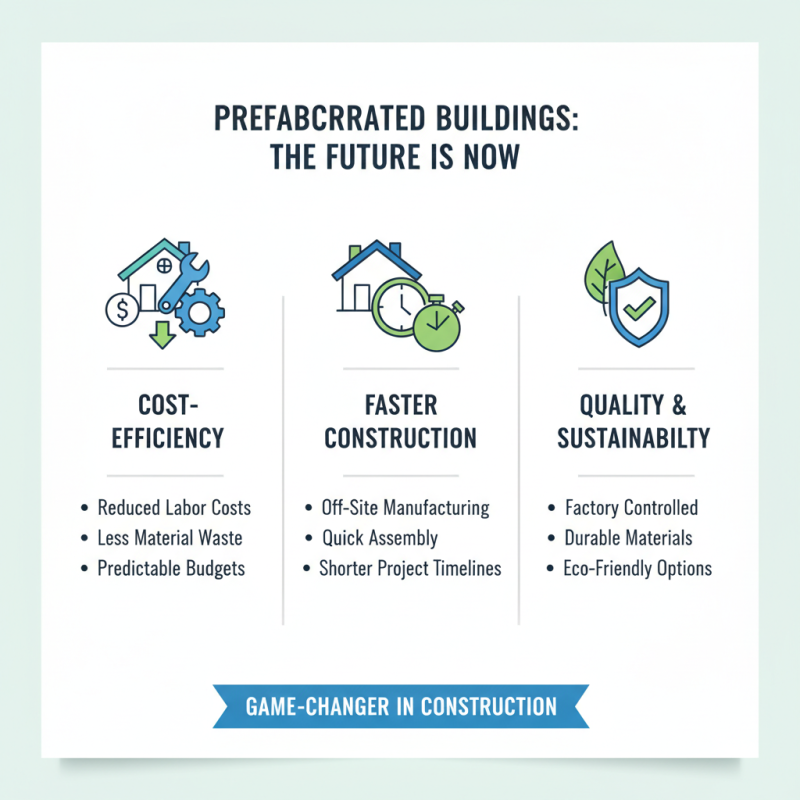

Advantages of Prefab Buildings: Cost-Efficiency and Sustainability

Prefab buildings, or prefabricated structures, are gaining popularity for their cost-efficiency. These buildings are constructed off-site. They are then transported to the final location for assembly. This method significantly reduces construction time. Many consider this a game-changer in the building industry.

Sustainability is another major advantage. The materials used in prefab buildings often minimize waste. The controlled factory environment helps achieve efficiency in resource use. Builders can recycle leftover materials easily. However, not all prefab options are eco-friendly. Some construction methods still rely on non-sustainable materials, demanding a closer look.

Cost savings are evident, but there can be issues. Site conditions can complicate installation. Transporting prefab units can also incur unexpected costs. Not all designs fit every setting, leading to potential adjustments. This might reduce the initial cost benefits. Thoughtful planning is essential to navigate these challenges effectively.

Prefab Building Materials: Common Choices and Their Benefits

Prefab buildings have gained popularity for their efficiency and versatility. The materials used in these structures play a crucial role in their appeal.

Wood, steel, and concrete are the most common choices. Each material has its unique benefits. For instance,

wood is lightweight and offers natural insulation. It can create a cozy atmosphere.

However, it may not be the best option in humid climates due to potential rot.

Steel frames are another popular choice. They provide excellent strength and durability. This makes them ideal for commercial buildings. Yet, steel can be prone to rust without proper treatment.

Concrete, on the other hand, is incredibly sturdy and requires minimal maintenance. It also offers great fire resistance. However, it can be heavy and challenging to transport.

When selecting materials, consider the location and purpose of the building. Each material comes with pros and cons.

Understanding them can help in making informed decisions. It’s important to reflect on these choices. Are you prioritizing sustainability? Or focusing on cost efficiency? Finding the right balance is key.

Market Trends in Prefab Construction: Growth Statistics and Innovations

The prefab construction market is changing rapidly. Advances in technology are driving growth. In recent years, the popularity of prefab buildings has surged. They offer speed and cost savings, appealing to developers and homeowners alike. Many believe this trend will continue. However, challenges and misconceptions remain.

Statistics show impressive growth in prefab construction. Reports indicate a steady increase in market size. Efficiency and sustainability are driving this movement forward. Some builders now use eco-friendly materials. Innovations in design make these structures more attractive. Yet, some still find prefab buildings lacking in aesthetic value. This is a point of contention for traditionalists.

Investors are also focusing on prefab solutions. The return on investment is often higher compared to conventional builds. Yet, there are areas for improvement. Quality control can sometimes vary. Customers should be cautious and do their research. Ultimately, the future holds promise, but attention to detail is necessary for success in this growing sector.

Related Posts

-

Top Prefab Building Designs for Modern Construction Trends?

-

10 Essential Tips for Maximizing Your Construction Site Container Efficiency

-

Top 5 Benefits of Living in a Container House You Need to Know

-

Exploring the Future of Modular Building: Top Innovations Shaping Sustainable Construction

-

What is a Folding Container House? Exploring Trends, Benefits, and Market Growth in Modular Housing

-

Top 10 Benefits of Modular Buildings for Modern Construction